Engine bearings – essential for smooth operation

Engine bearings are precision components that support the crankshaft and other rotating elements inside the engine. They ensure minimal friction, absorb mechanical loads, and help maintain alignment under high stress. Whether used in industrial machinery, marine engines or stationary power units, engine bearings play a vital role in durability and performance.

Function and benefits

An engine bearing serves as a smooth, low-friction surface between moving parts. It allows the crankshaft and connecting rods to rotate freely while maintaining precise clearance. High-quality motor bearings reduce wear, dampen vibrations and distribute engine loads evenly. The key benefits include:

- Reduced friction and heat in rotating assemblies

- Protection of crankshaft and connecting rods from wear

- Longer service life and improved engine reliability

In marine engines, marine bearings are specially designed to resist saltwater corrosion and operate under continuous heavy loads.

Types and applications

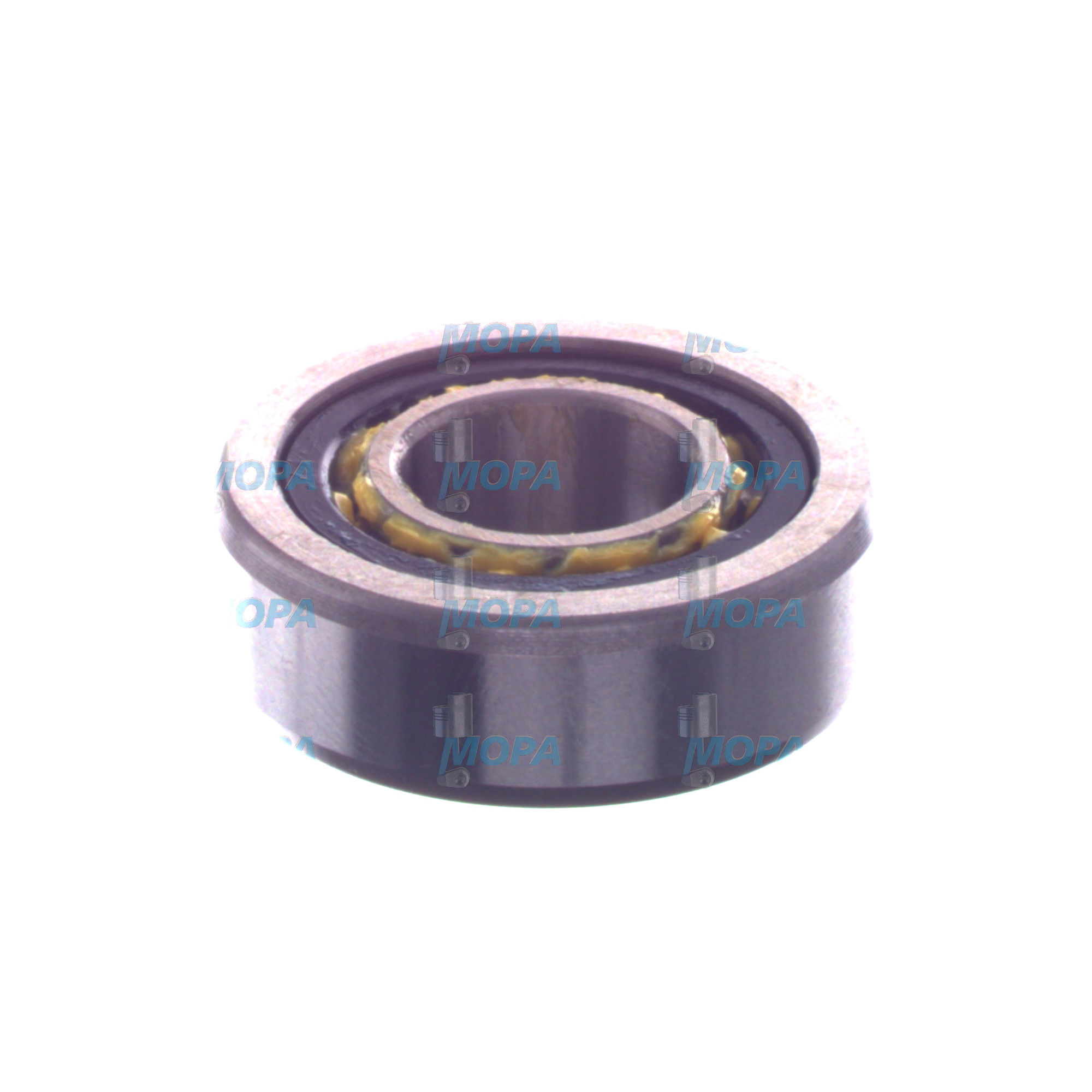

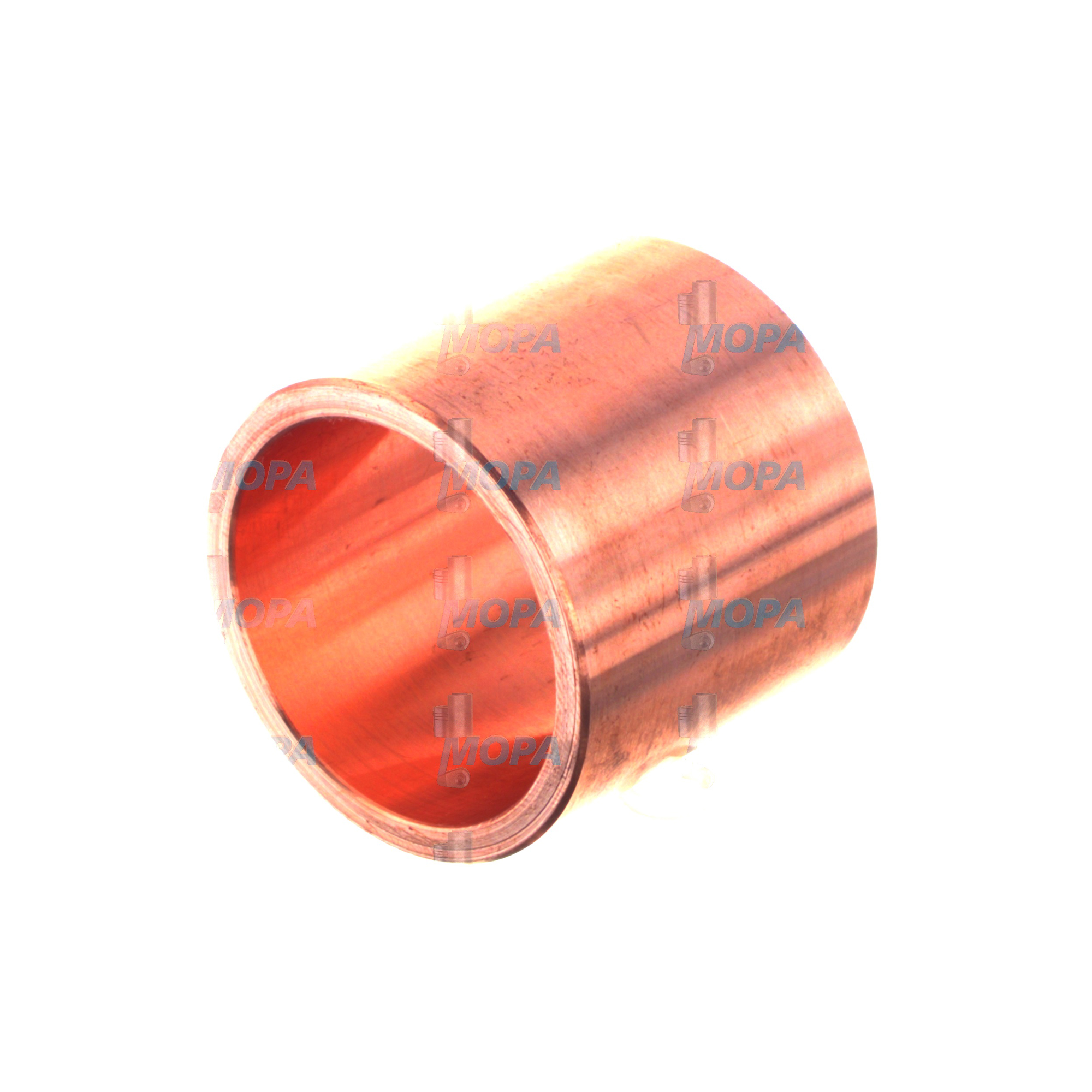

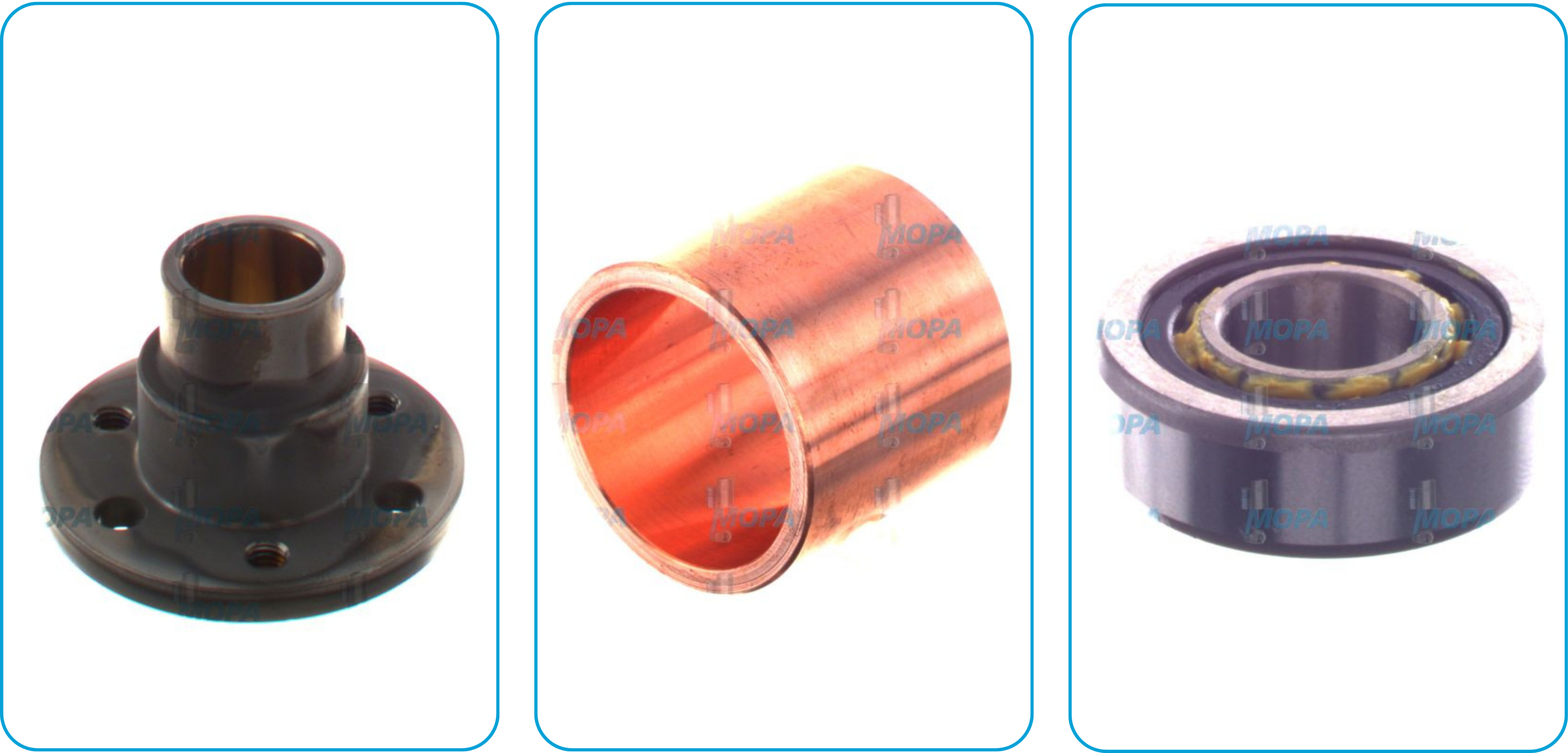

There are several types of engine bearings, including main bearings, rod bearings, camshaft bearings and thrust washers. Each has a specific function and must be matched precisely to the engine's design. Motor bearings are used in diesel and gas engines of all sizes – from passenger vehicles to marine propulsion systems and industrial generators.

Marine bearings often feature additional coatings or use corrosion-resistant alloys to withstand harsh environments. Correct bearing selection and installation are crucial for preventing premature failure and avoiding costly engine repairs.

Materials and maintenance

Engine bearings are typically made of multi-layered materials such as steel, aluminum, copper-lead or tri-metal alloys. These materials combine strength with conformability and fatigue resistance. Proper lubrication is critical to prevent metal-to-metal contact and overheating.

We supply a wide range of engine bearings and matching components suitable for MTU, Deutz, MAN, Volvo Penta and MWM engines – with fast availability and OEM-level quality for industrial and marine applications.

FAQ

What is an engine bearing?

An engine bearing is a precision part that supports rotating components like the crankshaft, allowing them to spin smoothly under load. It minimizes friction, controls motion and distributes force to protect critical engine parts.

How to replace engine bearings?

Replacing engine bearings typically requires engine disassembly. The crankshaft must be removed, old bearings extracted, and clearances measured precisely before installing new ones. Professional tools and technical knowledge are essential for a safe replacement.

Cost to replace engine bearings?

The cost to replace engine bearings varies depending on engine size, type, and labor. For industrial or marine engines, it can range from several hundred to several thousand euros, especially if crankshaft grinding or additional parts are required.

What are marine bearings?

Marine bearings are specially designed for use in ship engines and propulsion systems. They are built to handle constant load, vibration and corrosion caused by saltwater environments, and are essential for long-term marine engine reliability.