Clutch motor – precise power transfer

A clutch motor is a key component in powertrain systems, enabling controlled engagement and disengagement between engine and driven components. Whether in marine propulsion, stationary generators or heavy machinery, the right clutch motor ensures smooth torque transfer and system protection. Especially in dynamic environments, reliable engine clutches and engine couplings are essential for performance and durability.

Function and benefits

The clutch motor allows operators to connect or disconnect the power flow between engine and gearbox or other mechanical assemblies. This is vital during start-up, shifting, and overload protection. Key advantages of using a high-quality mechanical clutch or motor clutch include:

- Smooth power transfer without shock loads

- Protection of engine and drive components during overload

- Flexible operation in varying load and speed conditions

In marine environments, marine clutches and marine couplings are designed to handle long-duty cycles, salty atmospheres and frequent torque changes.

Applications and clutch types

Clutch motors are used in ships, industrial engines, compressors and power units. Depending on the application, clutch types include friction clutches, centrifugal clutches, hydraulic clutches and electromagnetic versions. A boat clutch or marine clutch is often integrated into marine transmissions for precise propulsion control.

Engine clutches and couplings must be perfectly matched to torque, RPM and shaft dimensions. In marine systems, marine couplings also compensate for alignment errors and dampen vibrations – ensuring smooth and safe propulsion under varying sea conditions.

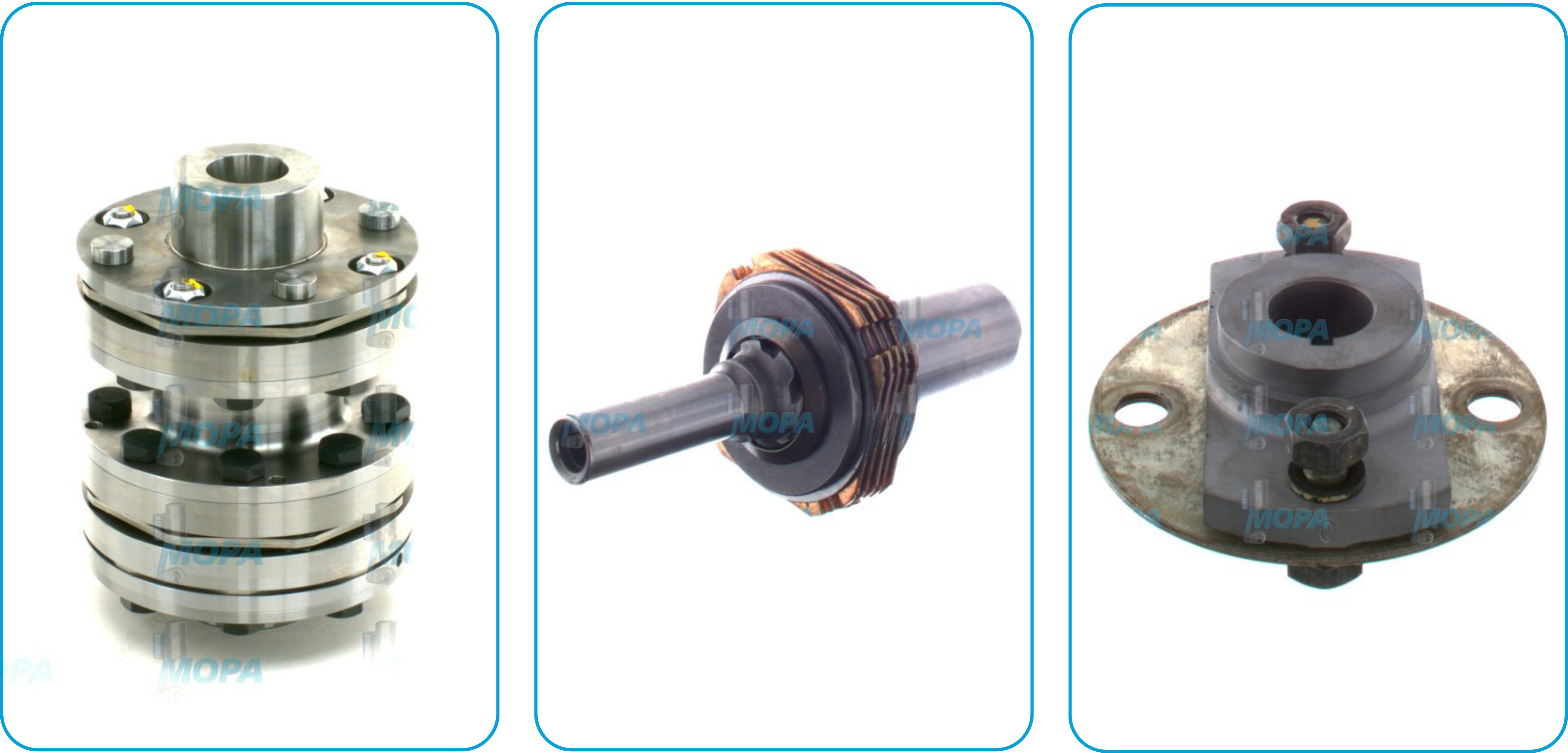

Construction and materials

Clutch motors and engine couplings are made from high-strength steel, cast iron or composite materials. Components such as friction discs, hubs and springs must resist heat, pressure and wear. A mechanical clutch must also ensure fast response and minimal energy loss.

All marine clutches and motor couplings in our range are suitable for demanding environments and long service intervals. We offer clutch solutions suitable for MTU, Deutz, MAN, Volvo Penta and MWM engines – with fast delivery and OEM-level precision.

FAQ

What is a clutch motor?

A clutch motor is a powertrain component that connects or disconnects the engine from driven machinery. It enables controlled starts, stops, and protection from overload by engaging or disengaging torque transfer as needed.

What is the difference between engine clutches and marine clutches?

Engine clutches are used across many applications, while marine clutches are specially designed for use in boats and ships. Marine clutches are corrosion-resistant, often water-cooled, and built to withstand constant torque changes and salty environments.

When should a motor clutch or engine coupling be replaced?

Motor clutches and engine couplings should be replaced if there are signs of slipping, vibration, overheating, or abnormal noise. Regular inspections and preventive replacement help avoid damage to the transmission or engine.