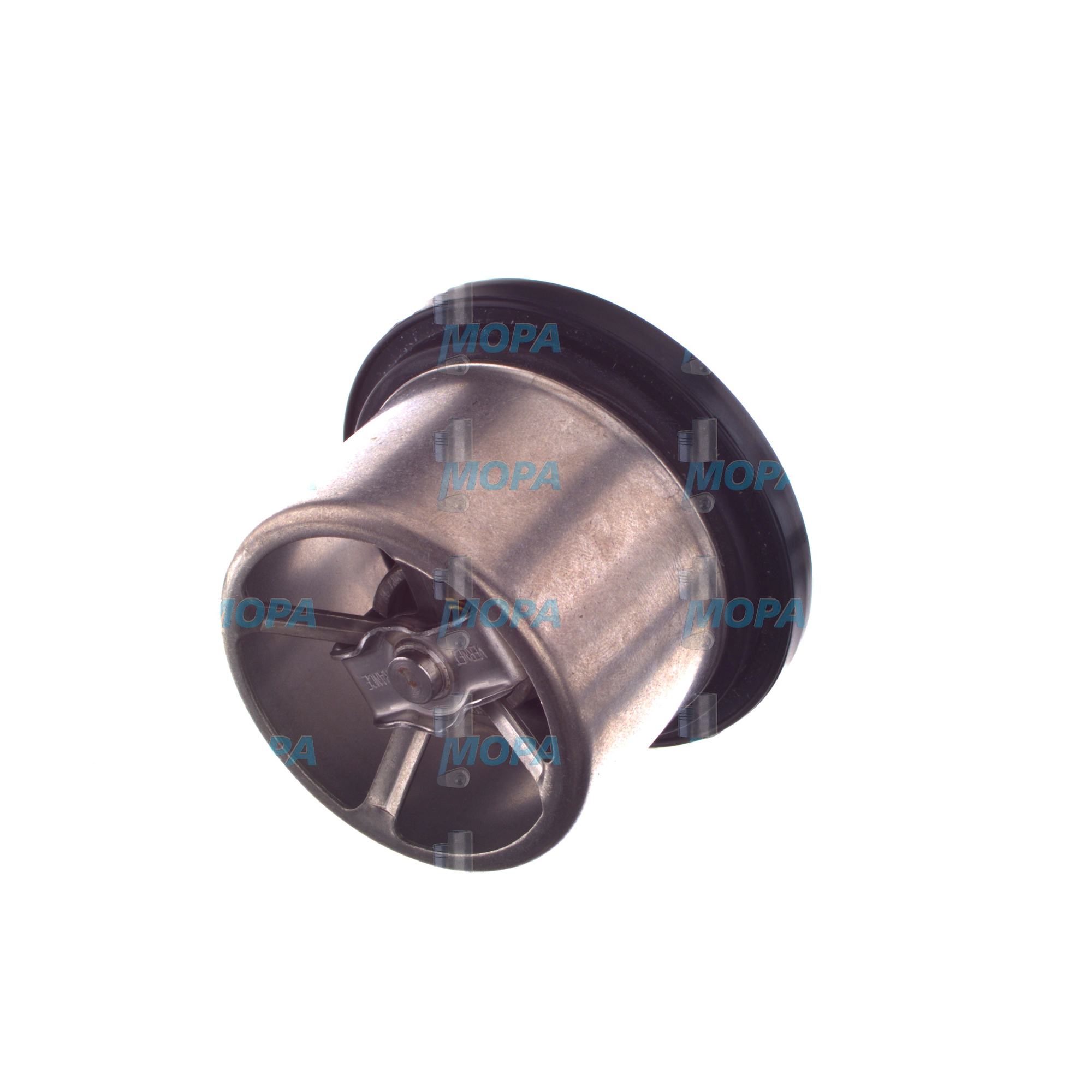

Engine cooler – efficient components for engines & machinery

An engine cooler is a critical component in maintaining safe and efficient engine operation. By dissipating excess heat generated during combustion, the engine cooler protects key components from overheating and ensures long-term reliability. Whether installed in industrial generators, marine engines or heavy-duty vehicles, a high-performance engine cooler is essential for thermal stability and operational safety.

Function and benefits

The primary role of an engine cooler is to regulate engine temperature. As the engine runs, it generates significant heat due to combustion and friction. The engine cooler transfers this heat to the ambient air or a separate cooling circuit, preventing temperature spikes. Benefits of using a high-quality cooler engine setup include:

- Improved thermal efficiency and stable engine performance

- Extended service life of components such as pistons, valves and seals

- Protection against overheating and system failures

A cooler motor runs more efficiently, especially under heavy load or in demanding environments such as marine or industrial use.

Types and applications of engine coolers

Engine coolers come in various types, including air-cooled, water-cooled and oil-cooled systems. Depending on the system design, a technical cooler may be integrated directly into the engine block or function as a separate external module. Applications range from ship engines and power plants to compressors and construction equipment.

The cooler engine configuration depends on engine size, heat load and ambient conditions. In marine environments, corrosion-resistant materials and robust construction are essential. Technical coolers must also allow for easy maintenance and integration into existing cooling circuits.

Materials, durability and service

Engine coolers are typically made of aluminum, brass or stainless steel for optimal heat conductivity and resistance to corrosion. The choice of material depends on the cooling medium (air, water or oil) and the operating environment. A technical cooler must withstand continuous thermal cycling and pressure fluctuations.

We supply OEM-compatible engine coolers for a wide range of applications, suitable for MTU, Deutz, MAN, Volvo Penta and MWM engines. All products are designed for long service life, efficient heat transfer and quick availability through our local stock.

FAQ

What is an engine cooler?

An engine cooler is a component designed to dissipate heat from the engine during operation. It prevents overheating by transferring excess thermal energy to the surrounding air or a cooling fluid. It is essential for safe and efficient engine function.

How does a cooler engine improve performance?

A cooler engine operates within an optimal temperature range, which improves combustion efficiency, reduces wear, and extends the life of internal components. Cooling also helps prevent power loss and maintains stable performance under load.

When should an engine cooler be replaced?

Engine coolers should be replaced if they show signs of leakage, corrosion, restricted flow or reduced cooling capacity. Regular inspection is recommended, especially in high-load systems such as marine or industrial engines.