Engine filter – performance for industrial & marine engines

A high-performance engine filter is essential for protecting your engine from contamination, abrasion, and premature wear. Whether in marine propulsion systems, stationary gas engines, or emergency power units, clean fluid and air are critical. OEM-grade engine filter solutions provide consistent filtration, flow stability, and compliance with manufacturer requirements—ensuring optimal efficiency, reliability, and system longevity.

What is an engine filter?

An engine filter removes harmful particles and contaminants from fluids (oil, fuel, air, coolant) before they enter critical engine systems. These filters play a vital role in preventing internal damage and preserving performance across all engine sizes and types. In diesel and gas-powered systems, even small contaminants can reduce efficiency, cause injector damage, or lead to premature part failure.

A complete filtration system may include oil filters, air filters, fuel filters, and separators — each with specific flow rates and media types tailored to the application.

Function and benefits of engine filtration

The core function of a motor filter is to separate contaminants from engine fluids before they reach sensitive components like pistons, injectors, or turbochargers. A clean engine filter ensures full combustion efficiency, proper lubrication, and longer oil intervals. Marine operators and power plant engineers depend on consistent filtration to avoid unplanned downtime and protect capital equipment.

OEM-standard filter parts maintain correct micron ratings, flow capacity, and seal integrity—reducing maintenance intervals and protecting warranties.

Filter types, materials, and marine use

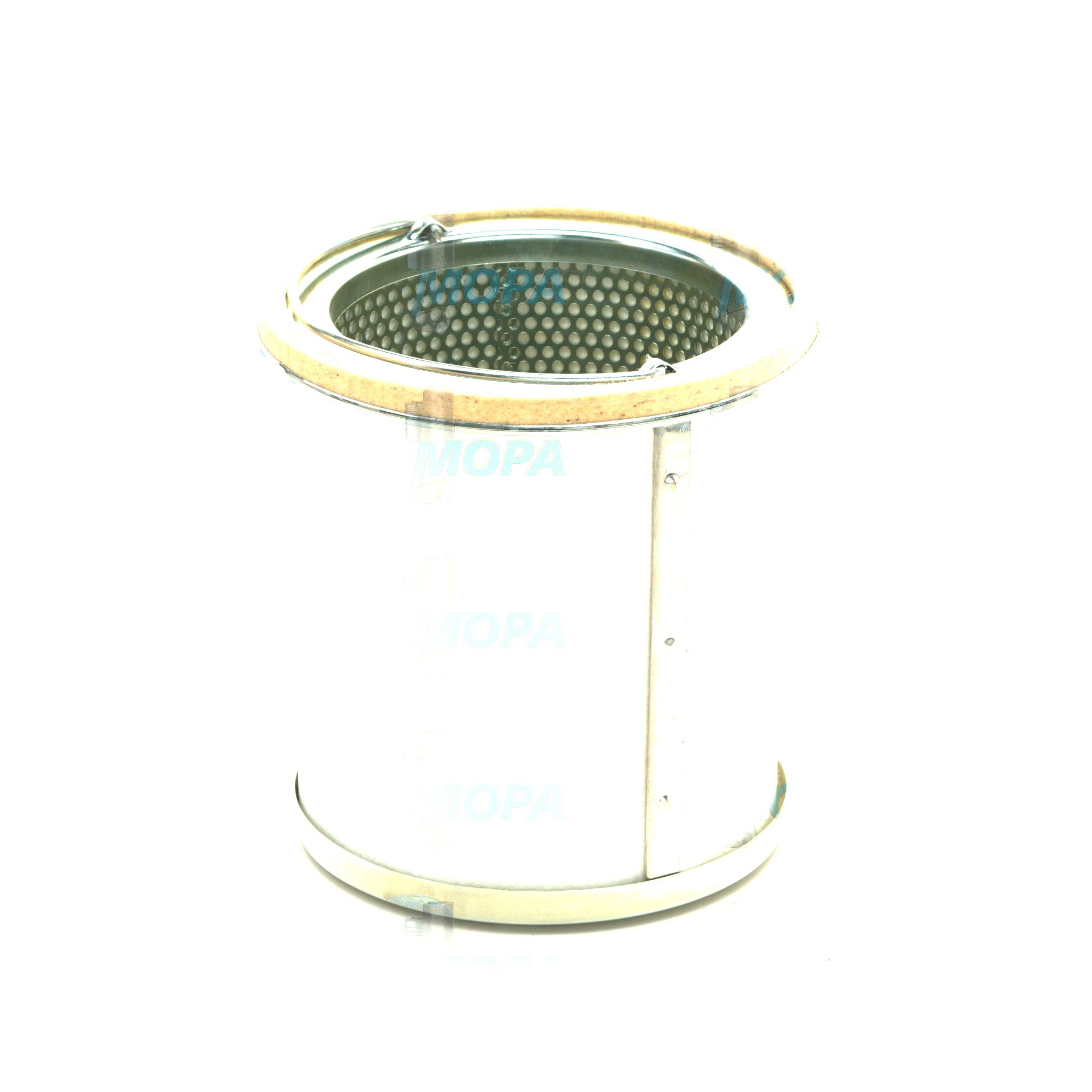

Engine filter variants include spin-on, cartridge, bag-type, and inline filters. Depending on fluid type and placement, media materials range from cellulose and microglass to high-performance synthetics or stainless-steel mesh.

In corrosive environments, such as in marine filter setups, robust housings and coatings are essential. A marine gas filter, for example, must manage high flow rates and resist saltwater exposure, while maintaining stable filtration under load.

Compatibility, OEM fit, and use cases

We offer a wide range of OEM filter solutions that match original engine specifications. These filters are suitable for:

- Marine engines (propulsion & generator sets)

- Industrial gas and diesel engines

- Backup power systems

- Compressors and heavy-duty equipment

Our engine filter options guarantee pressure resistance, thermal stability, and precision fit—whether you need a quick motor filter replacement or full fleet standardization.

Buying advantages with us

Choose your engine filter from our ready-to-ship stock and benefit from:

- Global DHL Express shipping

- Technical support for cross-referencing OEM numbers

- Competitive pricing

- Secure online ordering with flexible payment options

Related components for clean engine operation

In addition to engine filters, we offer sealing kits, brackets, filter heads, valves, and monitoring sensors—completing your fluid control setup. Matching the correct filter parts with system pressure and flow values ensures trouble-free operation and easy future maintenance.

Frequently asked questions about engine filters

What is an engine filter?

An engine filter protects the engine by removing contaminants from air, oil, or fuel before they reach critical internal components.

What are the types of engine filters?

Common types include:

- Oil filters

- Fuel filters

- Air filters

- Marine gas filter systems

- Inline and cartridge filters

Each type is engineered for specific flow rates, pressures, and filtration accuracy.