Fittings – connection components for engines & systems

Fittings are essential elements in engine systems, industrial machinery and marine environments. As mechanical connection points, they ensure tight, durable and vibration-resistant links between components. Whether you're dealing with marine fittings for boats or engine fittings for industrial motors, high-quality fittings are critical for maintaining operational safety and performance.

Function and benefits

Fittings serve as interfaces between hoses, pipes, housings and mechanical units. In engine systems, reliable engine fittings guarantee that fluids, gases and mechanical forces are securely transferred. Typical benefits of using precision-engineered fittings include:

- Secure and leak-free connections even under high pressure

- Resistance to corrosion, vibration and thermal stress

- Compatibility with various systems – from engines to pumps and cooling circuits

In marine environments, fittings must additionally withstand saltwater exposure and continuous load changes, making marine fittings a category of their own in terms of robustness and reliability.

Types and applications of engine and marine fittings

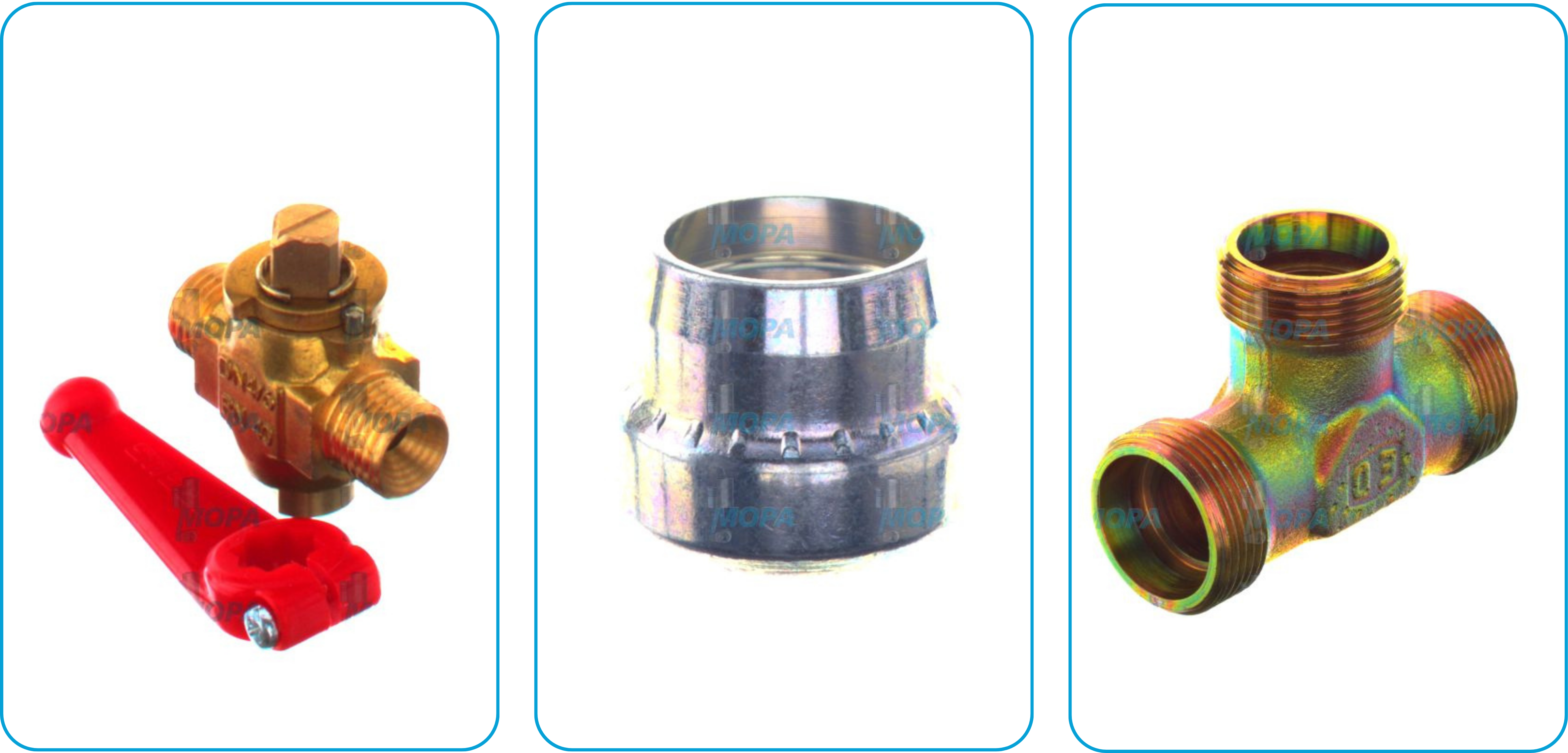

The category of fittings includes threaded connectors, quick couplings, hose connectors, elbows and T-pieces. Depending on the application, these are used in fuel systems, lubrication circuits, hydraulic control systems or exhaust units. In marine settings, boat fittings must also meet international safety and classification standards.

Engine fittings are commonly integrated in high-load environments such as diesel engines, gas turbines and power units. These fittings must be both dimensionally precise and material-optimized to support system pressure and dynamic loads.

Materials and design features

Fittings are typically made from stainless steel, brass, aluminum or composite materials. In some cases, coatings are applied to improve resistance to corrosion or abrasion. Boat fittings, in particular, are often anodized or sealed for protection against marine conditions.

Advanced design features such as O-ring grooves, reinforced walls or vibration dampers improve the safety and lifespan of engine fittings. Depending on the system, fittings may also be part of quick-connect modules or modular armature systems used in motors and armatures.

Replacement and availability

Over time, fittings can become worn or corroded, especially in aggressive environments or under constant pressure. For safety-critical systems such as marine engines, timely replacement is crucial. We supply a broad range of fittings suitable for MTU, Deutz, MAN, Volvo Penta, and MWM engine types.

Whether you're working with engine fittings, boat fittings or components related to motors and armatures, our warehouse ensures fast availability and OEM-level compatibility. Each engine armature or connection unit is carefully selected for durability and ease of installation.

Questions and answers

What is fittings?

Fittings are mechanical components used to connect pipes, hoses or structural elements in engines, industrial systems and marine applications. They are designed to ensure tight, secure and durable connections and are available in many shapes, sizes and materials.

How do fittings work?

Fittings work by mechanically joining two components, often using threads, clamps or pressure seals. In engines and motors, engine fittings maintain the integrity of fluid and air systems, while in boats and ships, marine fittings are essential for safe and corrosion-resistant connections. In the context of motor armatures, fittings help align and stabilize moving parts within dynamic systems.