Hoses – OEM for industrial and marine engines

Hoses are essential components for transporting coolant, oil, air, and fuel within industrial, marine, and generator engines. From pressure lines to return flow or venting, properly matched engine hoses support consistent performance and long-term reliability. Whether used in compact gensets or large propulsion systems, high-grade hoses reduce wear, improve temperature stability, and simplify maintenance across all application types.

What are hoses used for in engines?

Hoses are flexible tubing components that connect engine parts for the purpose of fluid and air transport. They carry coolant between the engine block and radiator, deliver fuel to injection systems, and vent gases through breather or return lines. In marine engines, marine hoses must resist saltwater, vibration, and continuous temperature cycling, while motor hoses for land-based equipment are built for thermal expansion and pressure loads. Specific engine tubing is also used to route low-pressure air or manage emissions.

Function and benefits of engine and marine hoses

- Secure transfer of coolant, fuel, oil, or air

- Reduced vibration transfer between rigid components

- Resistance to chemicals, salt, and temperature extremes

- Quick service access through modular fittings

- Improved safety by isolating thermal and pressure zones

Properly sized engine hoses contribute to performance stability. In marine systems, marine hoses and fittings form closed systems that withstand corrosion and pressure surges. On land, motor hoses are often part of emission and cooling loops.

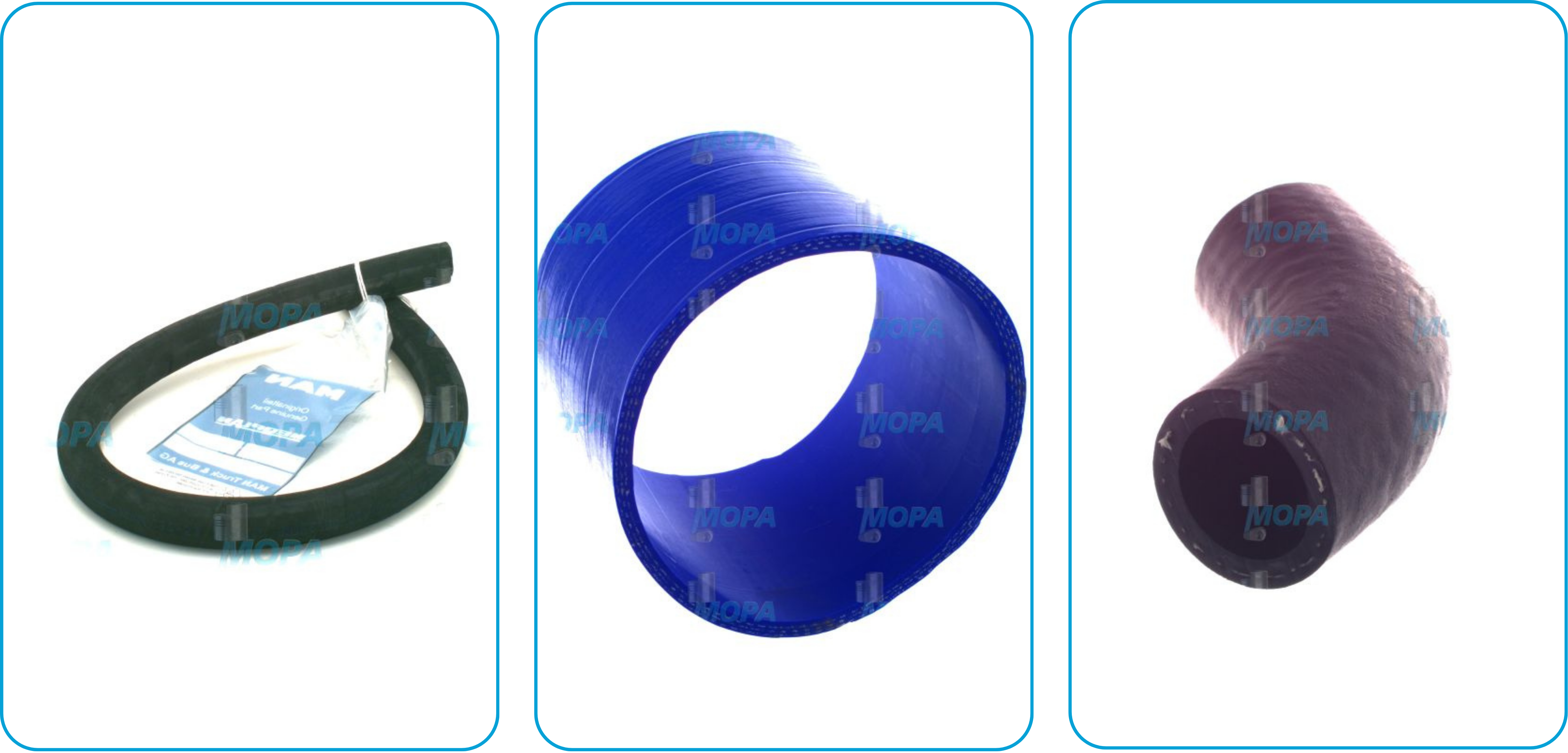

Types and materials used in hoses

- Reinforced rubber hoses for coolant and air

- Silicone hoses for high-heat and low-pressure areas

- Braided or wrapped tubing for vibration-sensitive zones

- Flexible exhaust and breather hoses

- Custom hose adapter for boat motor installations

Engine hose construction depends on its role: fuel hoses are often lined for hydrocarbon resistance, while marine hose products must meet safety standards for fire and burst resistance. Modern materials also include EPDM, nitrile, and fluorosilicone for specialized functions in power systems.

Compatibility and sourcing

We supply high-performance hoses suitable for MTU, Deutz, MAN, Volvo Penta, and MWM. All components are selected for chemical compatibility, temperature resistance, and connection reliability. Whether you're replacing a coolant engine hose or retrofitting with a new hose adapter for boat motor installations, we support precise selection based on diameter, length, and engine layout.

With our large stock and fast shipping, we help avoid unnecessary downtime—whether for planned service intervals or emergency repairs.

Application areas for industrial and marine hoses

Marine hoses are used in propulsion engines, bilge systems, exhaust loops, and seawater cooling lines. In industrial and stationary engines, motor hose products deliver oil and coolant to control thermal loads. Across all applications, properly routed engine hoses protect adjacent components and maintain system pressure during load changes or thermal expansion. Modular solutions simplify installation, especially in confined spaces or mobile setups.

Advantages of buying from us

As a B2B supplier, we offer:

- Fast DHL Express shipping from our extensive stock

- Support for selection and part identification

- Online ordering optimized for technical buyers

We support engineers and technicians with experience-based product selection and quick availability. Our offerings cover full hose sets as well as individual lengths, elbows, and marine hoses and fittings for on-site installation.

Related components to hoses

When replacing hoses, it is common to also exchange hose clamps, seals, gaskets, and vibration dampers. In marine applications, compatible adapters and through-hull fittings may also be required. We supply all related parts needed for safe and effective hose replacement in modern engine systems.

Frequently asked questions about engine hoses

What is a breather tube for on an engine?

A breather tube allows gases and pressure to escape from the crankcase or valve cover, preventing buildup and ensuring engine ventilation.