Motor magnets – magnetic components for precision

Motor magnets are key elements in electric and electro-mechanical systems, enabling controlled movement, switching and rotational energy conversion. Whether used in starters, solenoids or generators, high-quality motor magnets ensure efficient performance and durability. In industrial, marine or engine-driven applications, magnetic precision is essential for reliability and response accuracy.

Function and benefits

Motor magnets convert electrical energy into mechanical movement or maintain magnetic fields in rotating and switching systems. They are found in solenoid motors, starter assemblies, and many types of engine-related actuators. Key advantages of properly selected engine magnets include:

- Efficient electromagnetic force for movement and switching

- Reliable function under high load and heat conditions

- Compact design with long service life

Whether in marine engines or stationary systems, mechanical magnets play a central role in solenoid valves, relays, sensors and magnetic drives.

Types and applications

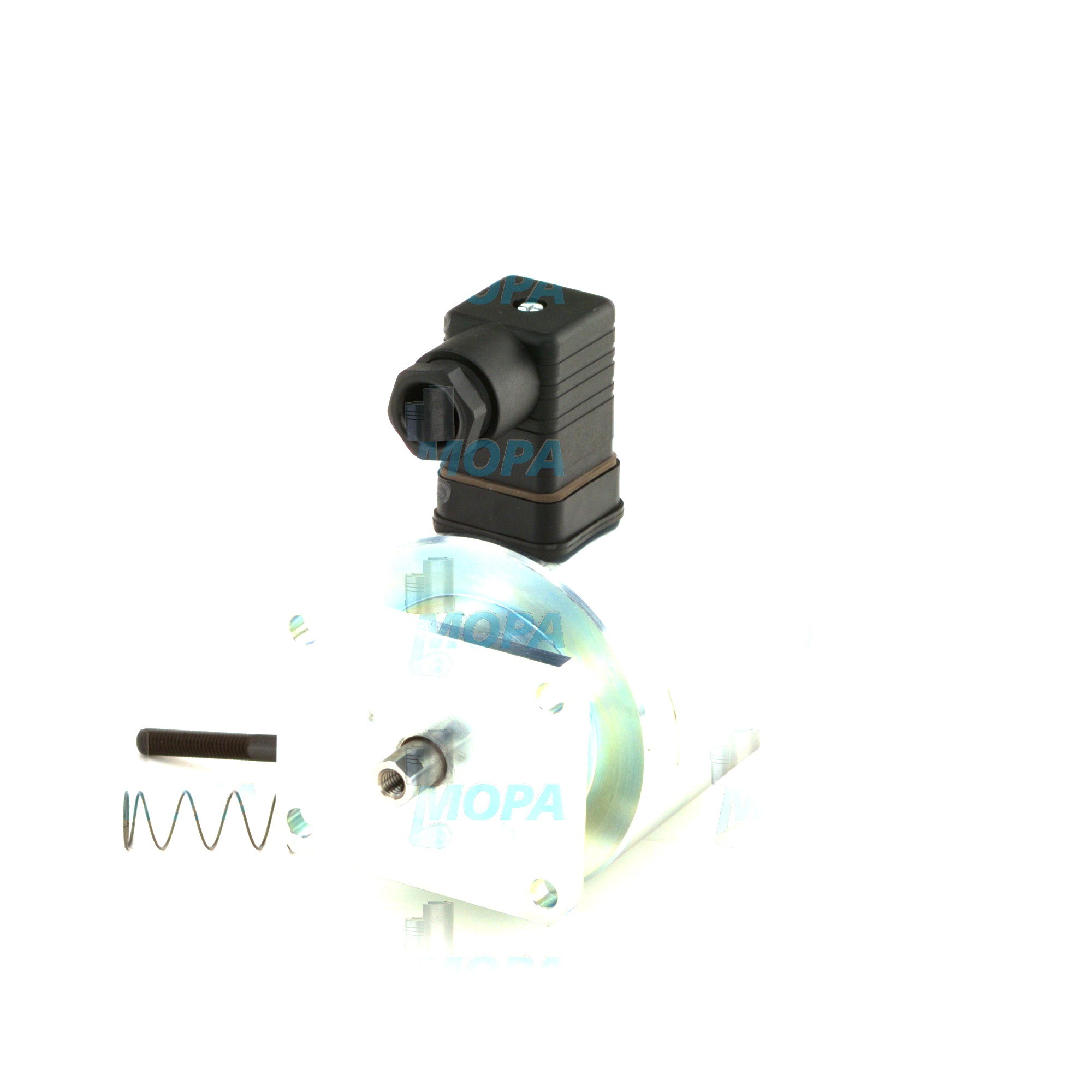

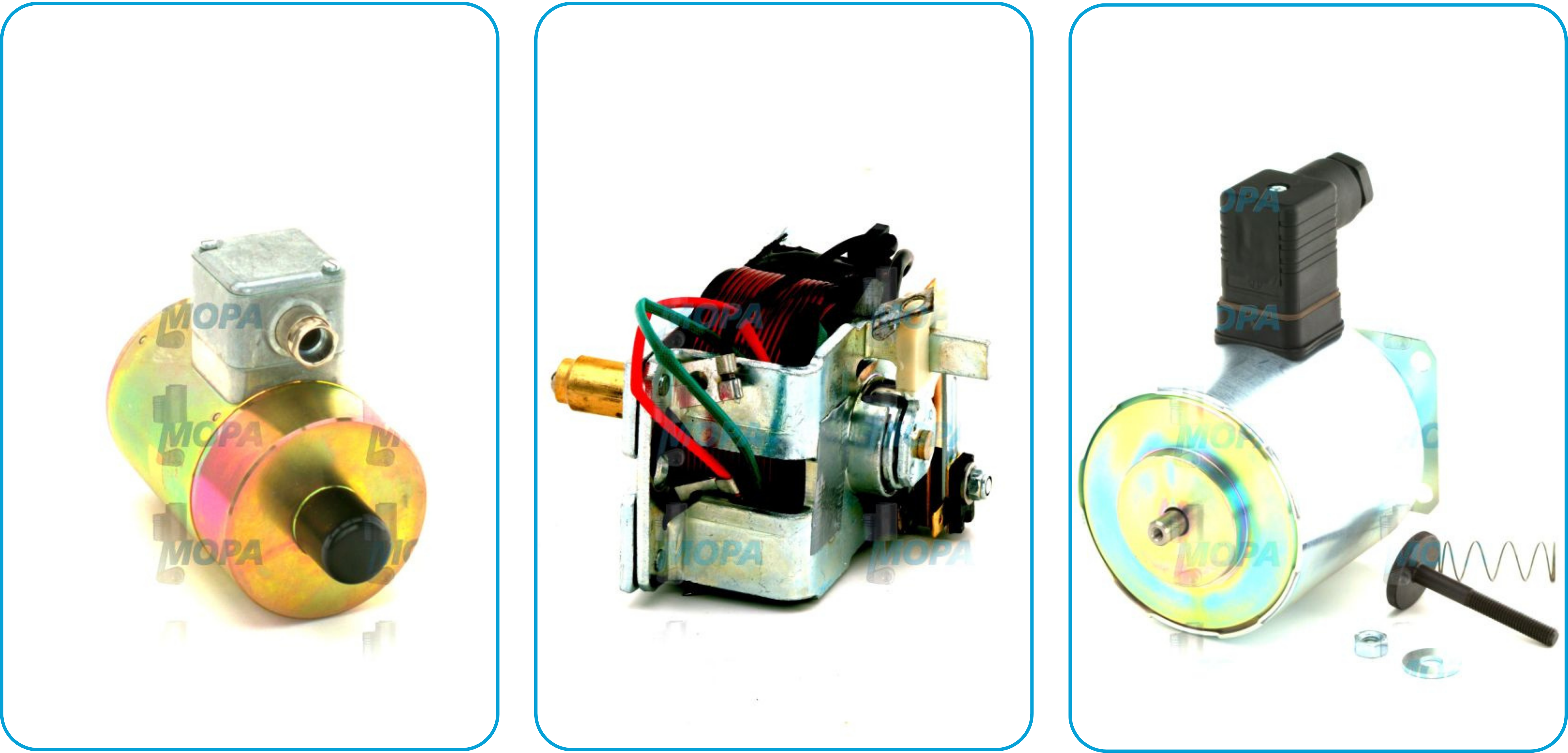

Magnet elements are used in various formats – permanent magnets, electromagnets, ferrite or rare-earth materials – depending on application requirements. In solenoid motors, magnets work with coils to control movement in fuel systems, starting units or hydraulic valves. Solenoid parts such as armatures and plungers rely on consistent magnetic response for accurate control.

In marine environments, marine magnets must resist corrosion, salt exposure and vibration. These magnets are often embedded in watertight housings or sealed components. Our product range includes magnet components for MTU, Deutz, MAN, Volvo Penta and MWM systems – designed for heavy-duty use and fast availability.

Material and design

Motor magnets are typically made from neodymium, samarium-cobalt, ceramic or soft iron cores, depending on required strength, temperature resistance and magnetic retention. Coatings or housings are used to protect against corrosion, especially in marine magnets. Mechanical alignment, magnetic polarity and compatibility with control electronics must be considered when selecting magnet elements or solenoid parts.

FAQ

What are motor magnets used for?

Motor magnets are used to generate electromagnetic force in engines, solenoids, relays and drives. They are essential in enabling movement, switching and energy conversion in both electric and mechanical systems.

What is the role of magnets in a solenoid motor?

In a solenoid motor, magnets work with coils to create linear or rotational movement. When electric current flows through the coil, it generates a magnetic field that activates a plunger or core element – enabling controlled mechanical action.

Are marine magnets different from standard motor magnets?

Yes, marine magnets are designed to resist corrosion, moisture and vibration in harsh marine environments. They are often encased in sealed housings or coated with corrosion-resistant materials to ensure long-term reliability at sea.