Piston rings – essential components for engine performance

Piston rings play a vital role in maintaining the efficiency and reliability of combustion engines. They ensure a tight seal between the piston and the cylinder wall, contributing to optimal compression, reduced oil consumption, and long-term engine durability.

Sealing and compression

The sealing function of piston rings ensures effective compression in the combustion chamber. Proper compression is vital for engine performance, as it directly affects efficiency and torque. Without functioning engine piston rings, combustion becomes incomplete, leading to power loss, increased fuel consumption and higher emissions.

In many engine types, especially in large applications, the use of durable engine piston rings is crucial to long-term reliability.

Oil control and heat transfer

In addition to sealing, piston rings regulate the distribution of oil along the cylinder wall. They maintain a consistent oil film – not too much, not too little. They also help transfer heat from the piston to the cylinder wall.

This heat dissipation is especially important in piston rings for diesel engines, which operate at higher combustion temperatures. Using high-quality piston rings for diesel engines improves thermal stability and minimizes wear under extreme conditions.

Piston rings engine: design and application

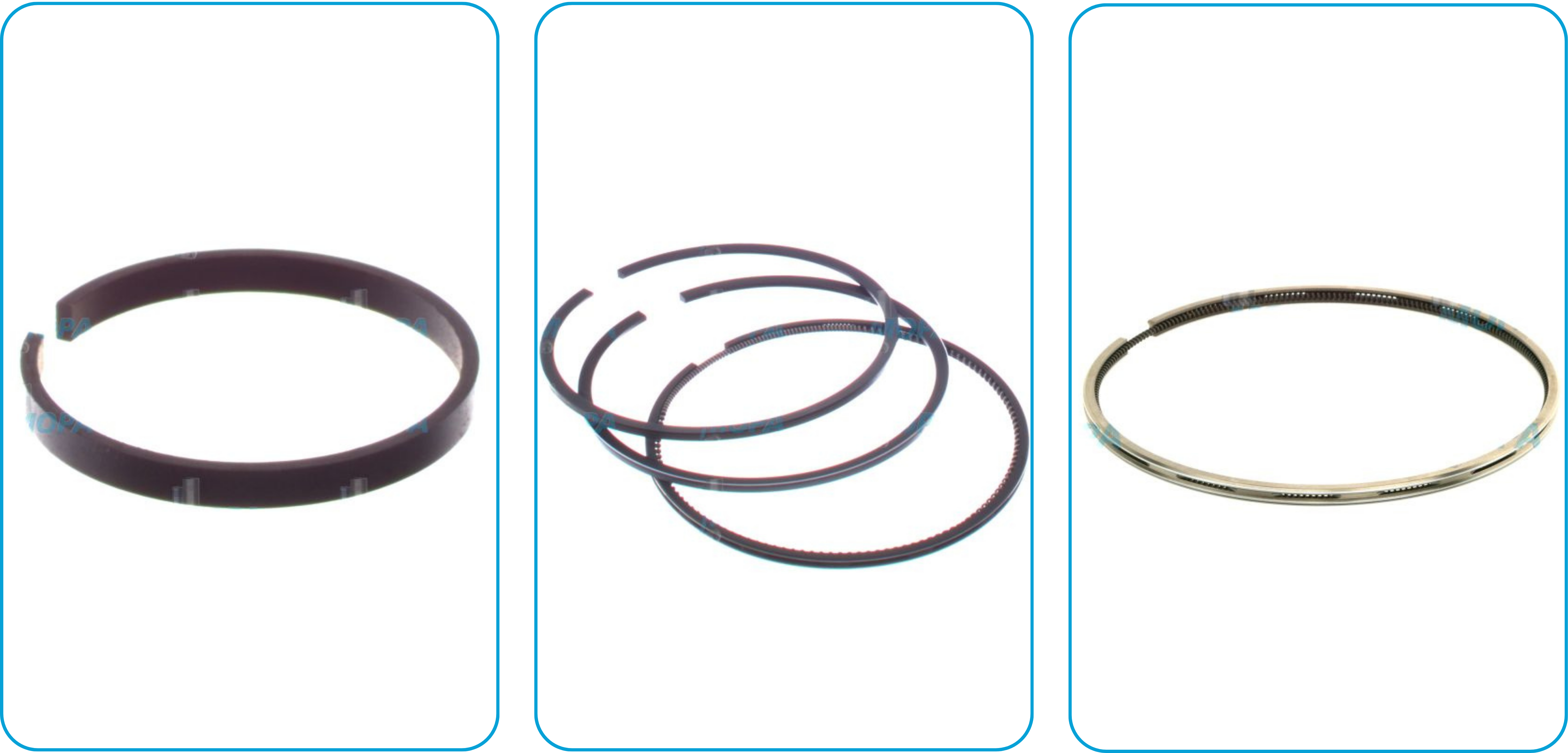

Types and materials

There are various types of piston rings: compression rings, oil control rings, and combined versions. Depending on the engine type and stress level, different materials such as cast iron or steel are used – often with coatings to reduce friction and wear.

A piston rings engine setup usually includes a precise combination of these ring types, customized for performance and durability.

Application areas

Piston rings are found in nearly all engine types – from passenger vehicles to marine engines and stationary industrial systems. Especially robust piston rings for diesel engines are designed to withstand extreme pressures and temperatures.

In a piston rings engine, these parts operate under constant motion and pressure, making material strength and dimensional accuracy essential. In marine and industrial use, durability and reliability under constant load are key.

Replacement and maintenance

Replacing engine piston rings typically takes place during engine overhauls. Precision, surface quality and compatibility with pistons and liners are essential.

As an experienced OEM parts supplier, we offer a wide range of compatible piston rings for various engine models – for maritime operations and industrial plants alike. Whether in overhaul kits or as individual components, rings and pistons must be carefully selected to meet OEM standards.

Related components that interact with piston rings

Piston rings don’t work alone – they are part of a highly integrated engine system. Other components also play crucial roles in ensuring engine reliability and performance. These are also available in our product range:

Exhaust system

The exhaust system is directly influenced by the efficiency of the piston rings. A tight seal ensures clean combustion and reduces strain on filters and catalytic converters.

Starter

Effective cold starts rely on adequate compression, which in turn depends on high-quality piston rings and starter. A well-sealed combustion chamber supports smooth starter operation, especially in any piston rings engine setup designed for heavy-duty use.

Gaskets and hoses

Gaskets and hoses maintain pressure and seal integrity throughout the engine system. They complement the function of piston rings by preventing leaks and pressure loss. In systems with moving rings and pistons, sealing quality is a vital safety and performance factor.

Coolers

Coolers help dissipate the heat transferred by the piston rings. They stabilize engine temperature and prevent overheating under high-load conditions.

Clutches, springs, and nuts

Clutches, springs and nuts are exposed to mechanical forces and vibrations originating from the engine. Their durability and performance are influenced by the pressure and motion in the piston assembly – the area where rings and pistons work together under extreme conditions.

Frequently asked questions about piston rings

What are piston rings?

Piston rings are metal rings on the piston that seal the combustion chamber, regulate oil flow, and transfer heat to the cylinder wall. They are crucial for engine performance and longevity.

How much is piston ring replacement?

The cost of piston ring replacement varies widely depending on engine size, design, and condition. It can be a major repair, as it often requires full engine disassembly.

How to install piston rings?

The rings are placed into the piston grooves with correct alignment and spacing. A ring compressor is then used to insert the piston into the cylinder safely.