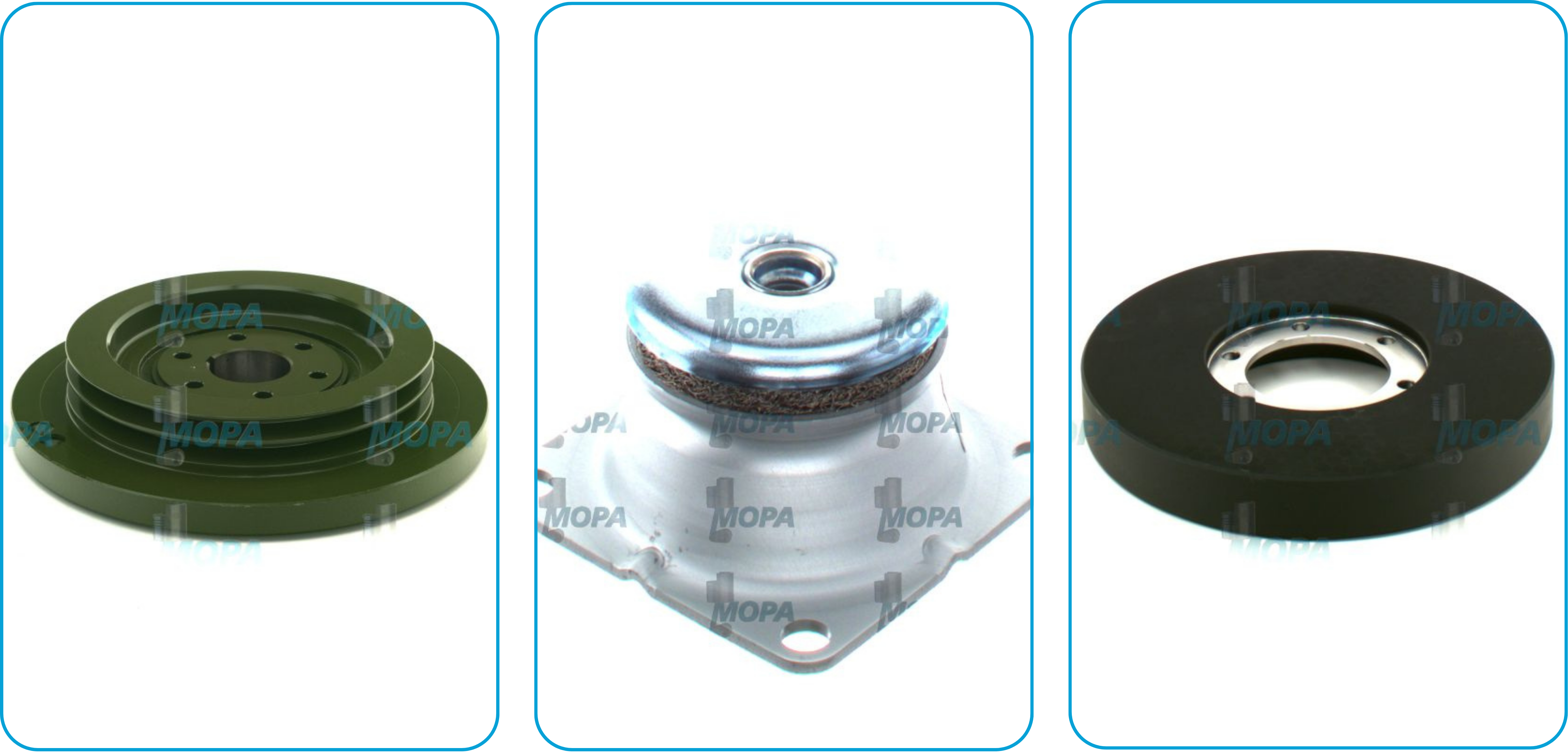

Vibration dampers – stabilization for engines

Vibration dampers are critical components in diesel and gas engines used in industrial, marine, and stationary applications. Their primary function is to minimize the harmful effects of torsional forces, mechanical oscillations, and structural stress caused by engine operation. In powerful propulsion systems or compact generator sets, vibration dampers in engine assemblies reduce wear, noise, and the risk of long-term component fatigue. Whether you're managing a single engine or maintaining a fleet, high-quality engine vibration dampers contribute significantly to system stability and service life.

What are vibration dampers?

Vibration dampers are mechanical elements designed to absorb and neutralize torsional vibrations in rotating engine components—typically at the crankshaft. These vibrations, if uncontrolled, can lead to crankshaft failure, excessive noise, and resonance in connected systems. Installed between rotating parts or at the engine's front end, engine vibration dampers help maintain mechanical balance and reduce dynamic stress during operation.

In marine engines, these components must also account for external motion, such as wave-induced vibration. Their performance is especially important in vibration damping mounts that support critical parts like compressors, pumps, and generator housings.

Function and benefits of vibration dampers

- Minimize torsional stress on crankshafts and gears

- Reduce engine-borne noise and structural vibration

- Extend the life of seals, bearings, and rotating assemblies

- Improve operator comfort and system reliability

- Support balanced motion in dynamic or mobile environments

In industrial systems, vibration damping improves measurement accuracy and protects sensor integrity. In marine engines, vibration dampers in engine configurations reduce resonance transferred to the hull or superstructure.

Types and vibration damping materials

- Elastomer dampers using flexible rubber elements

- Viscous dampers with internal silicone or fluid resistance

- Friction-based designs for modular engine platforms

Each system uses specialized vibration damping material to manage frequency and amplitude across defined ranges. In vibration damping mounts, this includes treated polymers or layered metal-rubber combinations—especially in high-load marine systems. Our range includes both bolt-on and custom-insert types, suitable for new builds and retrofits.

OEM compatibility and sourcing

We supply high-performance vibration dampers suitable for MTU, Deutz, MAN, Volvo Penta, and MWM. Whether for main propulsion, generator sets, or auxiliary equipment, our components match OEM-level specifications for fit, torque resistance, and material properties.

Thanks to a broad stock base and fast shipping, we offer rapid availability of standard and marine-specific dampers—ideal for unplanned repairs or scheduled replacement cycles.

Use cases and typical applications

Vibration dampers are used across marine and industrial systems where mechanical rotation must be stabilized. They are found in engine front ends, generator couplings, compressor skids, and fuel injection systems. In marine applications, vibration damping mounts reduce shock transfer between engine blocks and structural frames.

In all sectors, vibration-related fatigue is a major cause of premature failure. Using the correct vibration damping method extends maintenance intervals and protects peripheral systems.

Buying advantages with us

As a B2B partner, we provide:

- Quick DHL Express delivery from a large on-site inventory

- Components suitable for major engine platforms

- Technical support for part matching and application checks

- Efficient online ordering for industrial buyers

We support technicians, engineers, and purchasing teams with fast access to trusted components—whether for full replacements or critical refits.

Related components to vibration damping

Vibration control is part of a larger system strategy. Commonly paired items include mounting brackets, shaft couplings, flexible joints, and protective gaskets. These components work together with vibration dampers to maintain long-term stability across demanding load cycles.

Frequently asked questions about vibration dampers

What is vibration damping?Vibration damping is the process of reducing mechanical oscillations using materials or systems that absorb and dissipate vibrational energy.

What is damped vibration?Damped vibration refers to a motion where amplitude decreases over time due to internal resistance or external damping components, such as a damper.